Nonlinear Analysis Services To Regulate Stress & Strain

Shrinking profit margins and the need to develop products faster requires design engineers to optimize existing designs or seek alternative concepts.

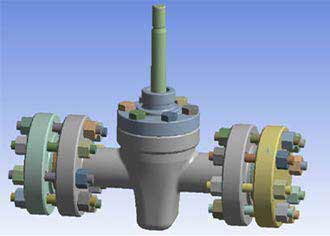

We specialize in simulating non-linear structural studies on engineering structures and industrial equipments to predict product behavior, undergoing large deformation right from no-stress condition to final loading conditions that lead to product failure. Our FEA analysts assist in predicting critical regions in the design subjected to high stress and deformation. We subsequently suggest possible design optimization to improve product performance and useful life cycle.

Domain Expertise/Application Areas

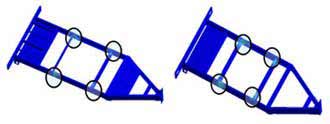

Evaluating the behavior of equipments and devices involving dynamic forces, our engineers help product designers to identify natural frequencies and mode shapes to reduce noise and vibration frequencies through finite element approach for: