Validate Product Designs from Inception to Save Time and Money

Posted by Bhaumik Dave on July 28th, 2015

As a product designer, engineer or a manufacturer, we know the importance of validating the idea of product design prior to plan a full-fledged production. Validation and verification is a green signal for the design that is ready to be mass produced with all the quality checks done to ensure its safety and reliability.

However, validation is easier said than done; in fact, it is one of the most difficult tasks any manufacturer or product designer would ever come across. But, without validation, conceptual design ideas are more prone to face failure rates when launched in the market. While virtual simulation such as CFD and FEA analysis is considered as one of the potential tools for product design evaluation, its use is mostly restricted to later stages of the product design, keeping the tool under-utilized.

Ideally, validating the product designs right from the early conceptual stages can drastically reduce the time and cost of product development. Simulating early and often can bring down the possibilities of last moment changes in the design drastically. With frequent simulations, it becomes easier to identify trade-offs and explore more design alternatives.

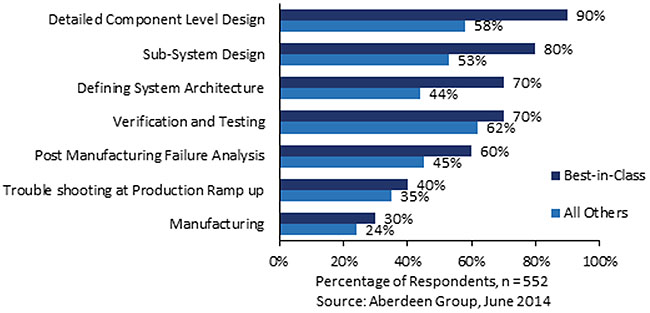

With more number of alternatives, product design can be optimized from multiple perspectives: cost, quality and performance. This importance of simulation is more seriously realized by best-in-class manufacturers as 90% of them apply simulation right from component level design to manufacturing.

To comprehensively realize the importance of early validation through simulation, few noteworthy points are discussed below:

Why Validate Designs from Inception?

- Validating ideas early can help in proving the reliability of assumptions and key hypotheses statements made during conceptualization. There are chances that many of the assumptions might be wrong or not properly defined. With simulation, the details on the product behavior can be visualized more accurately, bringing the conceptual design more close to reality.

- Most important benefit of validating early is to save time and cost by bringing down the possibilities of failure significantly. Decision to invest money and time on something unproductive for the market can be avoided as the chances of failure can be predicted from the beginning itself.

- Validation also enforces design engineers to get feedback from the end customers to realize the ease of use and ensure that product’s acceptability in the market.

- Early prediction through validation helps design engineers to identify whether they are on the right track or not. Changing the approach early can drastically reduce the cost and time.

- Finalized design will require less physical iterations, which will minimize the number of prototypes required and the investment of time required to test them.

- Product failure and warranty schedules can be defined more accurately, since the design constraints are already well-defined through their early validation.

- Post manufacturing validation through simulation can help improve the manufacturing processes and identify errors, eliminating the possibility of production scraps.

Incorporating simulation early to validate the product design is what best-in-class manufacturers prefer to do, to stay ahead in the market, meet project deadlines and hit their targeted revenues on time.