Using Shell Elements in effective way for Design Assessment

Posted by Bhaumik Dave on July 2nd, 2013

Shell Elements are popular mainly because of their applicability for thin structures. The advantage of using shell is the fact that the only shear on the free surfaces is in-plane.

As the normal to shell middle surface stays straight, the in-plane strain variation through the thickness can be assumed to be linear. However, this assumption is not valid at the edges of layered composite shell elements have different material properties at each layer.

In case of Design Assessment it is mainly for the user to decide when to go for shell elements; and when to model with solids. Shell Elements have their advantages as they are more appropriate to model thin structures. From meshing point of view also, shell mesh results with a better quality mesh.

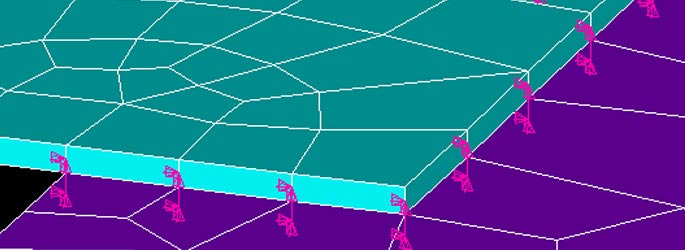

However, when there are mixed elements such as a mixture of solids and shell elements, it is difficult to connect these since solid elements usually have 3 Degrees of Freedom at each node however; shell elements have 6 Degrees of Freedom at each node. There is another variant of shell element having 3 Degrees of Freedom/node which should be used in case the objective of using shell elements is to have a better mesh.

From Design Point of view, it is easier to use shell elements if the aim is to assess and conclude the thickness required for a particular shape to sustain the required loading. Using shell elements for such problems reduces the efforts for pre-processing by considerable amount.

Shell elements are of relevance when we speak about structural elements and in that two dimensions are much greater than the third one. The varying features of the analyzed feature in the third direction can be abandoned. It is perfectly fine to say that static analysis of panel elements such as slabs or wall along with thin-walled spatial elements such as shells are of prime importance.

May be you like to read more about: FEA for Material Selection – Ensuring a High Performance Product Design