Use of Thermal Analysis for Optimization of Solidification Process

Posted by Bhaumik Dave on December 12th, 2013

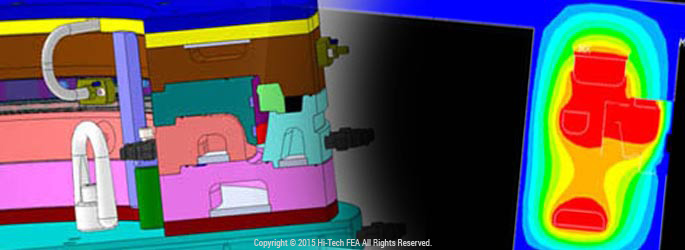

To avoid the cracks that may occur during Casting Processes of Aluminium Cylinder heads, a thermal analysis can be done to simulate the solidification process. For this, thermal and elastic-plastic theory should be used. We can also optimize the solidification by the results of simulation. As per thermal and elastic-plastic theory, the temperature and internal energy of the system are significantly variant during casting solidification process. As per the latent heat for solidification, the thermal analysis about casting solidification process is non-linear and transient. The residual stresses are generated during the process.

When these residual stresses are exceeding the yield stress, it can be concluded that crack is generated. We can use a 3D geometry of the Head and the sand mould. For the optimization of solidification process, we can select time of sand removing and convective heat transfer co-efficient as design variables and thermal stress as an objective function. The simulation results achieved thus can guarantee the minimized effects of residual stresses during solidification process.

The optimal design may be obtained with solidification time for a given casting being chosen as the objective function and employing constraints from the expert knowledge to avoid unacceptable thermal stresses and defects in the casting. In a typical design session, the cooling parameters are first varied to reduce the solidification time. If the solidification time does not reach the desired value, the pour temperature of the melt may be varied. If even this does not satisfy the requirements, the thickness of the mold wall may be changed. Thus, by first varying the operation conditions and then the dimensions and materials, the solidification time may be minimized or brought below a desired value.

May be you like to read more about: Different Types of Thermal Analysis