Seismic Qualification of Industrial Rack for Storing Computer Peripherals

Challenges:

- Provide a Seismic Test report with the aid of Finite Element Analysis method

- As competition increases, the demand for new Designs also increases asking for a quick turn around on New Product Development

- With these expectations, it becomes essential to focus on Designs which can be readily used with fewer number of Prototype Testing

Software Used: ANSYS Professional NLS 14.5

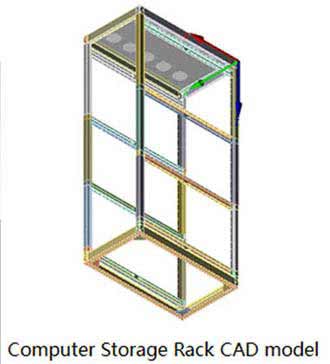

Solution: A 3D model of the Industrial PC Rack was constructed to perform finite element analysis. The analysis helped in determining the structural integrity and performance characteristics of the Industrial Rack System under different seismic loading conditions.

Computer Storage racks are normally used to mount servers or desktop peripherals. These racks providing structural support need to be compliant with the Bellcore standards, in order to maintain structural integrity under loaded conditions.

A leading computer storage rack manufacturer needed their rack design to be evaluated for structural integrity in seismic events, considering the Bellcore standards.

Solution:

A detailed three-dimensional (3-D) finite element (FE) computer model was constructed for seismic qualification analysis of the Industrial Rack. This seismic qualification was done for Bellcore zone 4 requirements.

The analysis was performed to determine structural integrity and performance characteristics of the Industrial Rack System under different seismic loading conditions. The objective of the work performed was to quantify the system performance characteristics under the influence of seismic inertia loads, based on the specification and applicable regulatory documents and industry standards.

Modal analysis was also performed to determine the lowest natural frequencies and associated mode shapes of the assembly. The seismic analysis was executed using the spectrum available using response spectrum method (SPRS: Single Point Response System).

Results indicated that all investigated components of the Industrial Rack Assembly will maintain their structural integrity during and after the specified seismic events for Bellcore zone 4.

Benefits:

- The seismic analysis results and margin of calculations for the rack assessed that the industrial rack design is suitable according to the Bellcore Seismic Testing Standard

- Assessment by FEA methodology shortened the design cycle, as FEA calculations suggested that the design will perform as per the required specifications

- The client had the First Prototype working as per the specifications required