Design Optimization of Gate Valve Body for High Pressure Fluid Flow Applications through FEA

Challenges:

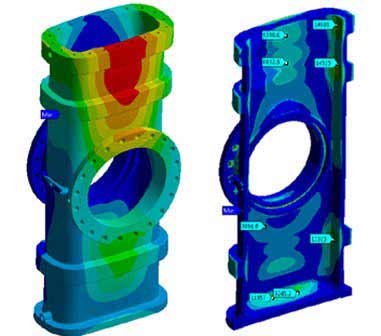

- Evaluating existing valve geometry to identify high stress concentration regions

- Identifying possible optimization on existing design space

- Ensuring appropriate boundary conditions to simulate real world conditions and predict accurate results

Software Used: ANSYS Professional NLS 14.5

Solution: The gate valve design was first analyzed as per the given loading conditions to measure the stress and deformation values across the geometry. To reduce the deformation value to an acceptable limit, the valve geometry was re-modeled with an additional rib on the outer surface. The following structural analysis for the new design showed considerable reduction in deformation values.

Gate valves must withstand stresses generated due to the flow of high pressurized fluid. While these valves possess complex geometries, there are chances of development of high concentration regions across the geometry. These stresses cause the valve body to deform and cause the valve to become inoperable.

There is a certain deformation limit for every valve based on the type of its application. A US based design consultant needed a quick solution to address the deformation issue related to their valve body design.

Solution:

The existing valve body was first analyzed under given operating conditions to identify stress concentration regions. It was observed that the deformation values across the geometry were exceeding the permissible limits. The structural analysis also helped in figuring out the material’s factor of safety across the geometry.

The new body design was suggested based on the analysis results by applying ribs, thereby providing additional structural strength to the valve. The subsequent structural analysis performed for the new design showed beneficial results, reducing the deformation below the specified limit.

Benefits:

- Improvement in design quality of the valve body

- Reduction in number of physical test trials required

- Early identification of design problem leading to shorter manufacturing time frame