Development of an Optimized Oil Storage Tank Design

Challenges:

- Identify alternative design solutions for the existing storage tank

- Ensuring the design’s geometrical feasibility for its actual application

- Maintaining the stress and deformation values to minimum

Software Used: ANSYS Professional NLS 14.5

Solution: The existing storage tank design was modified by providing additional cross support bars at the tank side walls, which provided structural strength and reduced the stress and deformation values considerably.

Designing a storage tank requires taking into account diverse factors, in order to avoid premature failure. Out of the several loads the tank has to accommodate, the load acting due to weight of the fluid to be stored is of prime importance. The fluid weight also induces stress over the tank surface, resulting into deformation and ultimately increases the chances of tank failure.

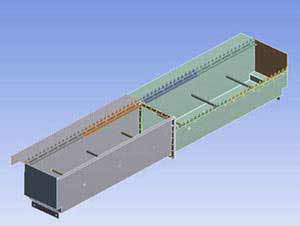

The client requested a similar solution for the storage tank designed to store oil. The major concern from the customer’s end was to re-develop the storage tank geometry, having the ability to withstand stress and minimize deformation values.

Solution:

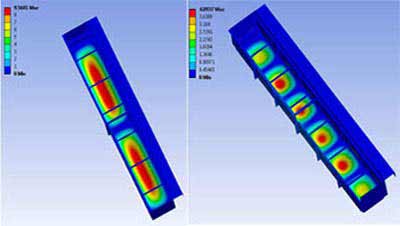

The existing storage tank design was first analyzed to measure the stress and deformation values, considering the weight of the oil. Despite the stress values obtained were within the permissible range, the deformation was present and needed to be addressed.

To minimize the deformation values, a new tank design was proposed, which included the application of additional support bars at the tank walls. The additional support enhanced the storage tank strength with 45% reduction in deformation values.

Benefits:

- Improved storage tank design to withstand the oil weight effectively without deformation

- Reduction in tank bulging due to excess strength provided by cross bars

- Improved tank life due to minimized stress generation

- Significant reduction in time required for physical tests