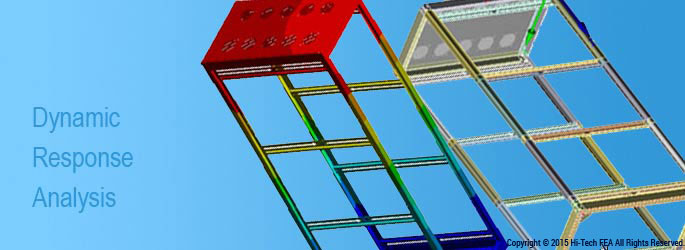

What is Dynamic Response Analysis and when it is used?

Posted by Bhaumik Dave on April 9th, 2013

Dynamic response analysis has become an integral method of engineering process of finite element analysis. It is largely used is semiconductor as well as in biotechnology industry. This practice of testing was launched in the year 1984 and this analytic process is employed for a wide range of measuring activities like nano meter level vibration issues interferometers, and atomic force microscopes to centimeter level vibration issues.

These issues are often found associated and emerged against the process of instrument off-shore rigs for availing accurate and practical result for short frequency operating deflection shape analysis. It is a part of structural dynamics for high resolution manufacturing process, imaging and testing systems, and this analytical process is also being used in nano-meter technology application as well as in micron technology implementation.

When Response Dynamics Analysis is Used?

In static studies loads are calculated as constant. Due to this assumption, static studies often overlook damping forces as well as inertial forces. There are several cases where the measurement of loads is not constant or they change with frequency or time.

Dynamic response study method is applied in these situations and the method/result of response dynamics analysis is applied here. In general where frequency of a load is calculated higher than 1/3 of the basic frequency, the method of dynamic response analysis is applied there. This analysis process is executed by software as it calculates the typical response of the simulation by gathering the contribution of each of the modes toward the loading.

The contribution of mechanical dynamic analysis depends on the load’s frequency content, magnitude, direction, duration, and location.

There are two objectives of Dynamic Analysis of Mechanical Systems. These two are

- Designing structural and mechanical systems in order to perform accurate without suffering from failure in dynamic setting

- For right implementation of modification for system’s features like geometry, material properties, damping mechanisms for reducing vibration effect.

Dynamic Analysis of Mechanical Systems: How It Helps

This testing process helps in industrial processes. Primarily it helps in R&D process for studying the dynamics of moving parts and the way how forces and loads are distributed all through a mechanical system in order to perk up and optimize a specific product performance. With the help of FEA method, linear vibration and transient dynamics can be well studied, but nonlinear motion and large rotations can be best measured by Dynamic Response analysis process.

Semi conductor industry widely involves extensive use of vibration sensitive equipment. The method response dynamics measures and calculates site evaluation and related issues, including the factors related to vibration site survey. The solution may involve reduction/isolation of the disturbance source, active cancellation of the disturbance at the sensitive tool, modification of the floor system, or tool improvement (such as with tuned mass dampers).

Dynamic response analysis is applied for SEM tool, FIB tool, ELF system, TEM tool, Atomic force microscope system, wafer stepper, profilometer, interferometer, electron microscope, CD SEM tool, SPM tools, and ellipsometer. However it is an intricate process, hence it is always wise to avail best service provider for availing best, accurate, and practical result.