Application of Computational Method for Cricket Bat Designers

Posted by Bhaumik Dave on July 9th, 2013

A number of popular sports such as tennis, badminton and baseball have benefited from extensive research in sporting equipment. Bat performance means the ball exit

velocity obtained after hit. Experimental assessment of bat performance is costly and tedious work. A computational finite element modeling approach may be used to predict the performance of the cricket bat as mentioned in vibration data.com/cricket_bat.pdf

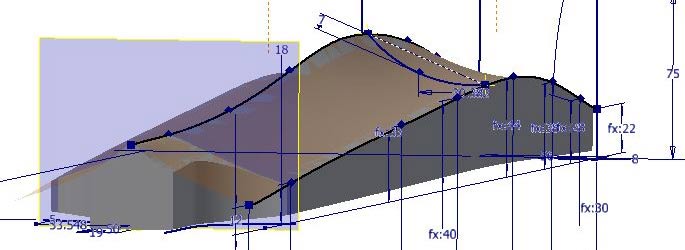

The dynamic interaction of a cricket ball and a bat can be computationally modeled using commercially available software ANSYS /LSDYNA. A finite element model of a ball should be created using a Visco elastic material model. When this ball model is used with finite element orthotropic model of cricket bat, the ball exit velocity is quantified. Modal analysis is also done to locate the region between the two nodes of fundamental modes of vibration. The relationship between the region between the nodes and the region which produces maximum velocity is established. This modeling procedure yields a credible methodology for bat designers to use finite element methods to characterize cricket bat performance.

The full cricket bat width is 10.8 cm. The full bat length is 96.5 cm. We all know that there is a term termed as bat swing which is used when the batsman practices the full power to execute the shots. Now the effort required to move the bat escalates as the weight of the bat increases. Hence; a lighter bat will allow superior swing and the chance of the ball hitting the middle of the bat intensifies. A heavier bat will require lot of effort to make a hit from the middle.

During impact; the vibration behavior of the bat corresponds to that of a unrestricted, non-supported bat whether regardless of firmness of the bat. The impact between bat and the ball is a collision between two objects. Modal analysis is carried out to locate the node points and the region of location of this node points. Relationship between nodes and the region which produces full ball exit velocity is established.

It is found that the region between the two nodes produces the maximum ball velocity. This region is also known as sweet spot. This region is between 0.12 m and 0.18 m from the bottom of the bat. Finite element models provide an exceptional simulation of the bat-ball impact and can be used to examine the ball exit velocity. This modeling procedure yields a credible practice for bat designers to use finite element methods to depict cricket bat performance.

May be you like to read more about : Application of Mechanical APDL to model Large Pipelines