FEA Consulting for Product Development & Design Validation

Developing high performance, economical products with reduced development schedules require manufacturers to adopt modern product design tools that provide key insights on product behavior right from early development stages.

We leverage capabilities of engineering firms and manufacturing organizations through design solutions, to evaluate product performance across multiple physics using finite element approach. Right from stress and deformation studies, thermal effects, fatigue life estimation to dynamic response to vibrations, our engineers help product designers to improve product designs from all aspects. Our team has delivered successful design projects for multiple domains including automotive, industrial equipments, building structures and electronics.

Our Expertise

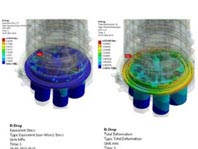

[su_accordion] [su_spoiler title=”Static Structural Analysis” open=”yes” style=”default” icon=”plus” anchor=”” class=””]- Nonlinear Stress Analysis

Our FEA analysts provide structural design solutions for product designers and manufacturers to evaluate the structural integrity of equipments and devices undergoing non linear deformation. Through prediction of stress and deformation due to loading applications, we assist in optimizing product design through finite element approach.

Read more - Linear Static Stress Analysis

We assist product design engineers to understand their product behavior against loading applications, designed to perform under yield point and simultaneously improve the structural integrity and useful life period.

Read more

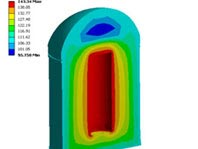

- Steady State Thermal

Engineers at HiTech FEA assist manufacturers in identifying thermal compatibility of their product design by predicting temperature distribution and resulting hot spots in the design. We help design engineers with possible optimization alternatives to improve the product design and resistance against thermal effects and resulting stresses and deformation.

- Transient Thermal

Our transient thermal analysis solutions are aimed to study the effects of high temperature on devices subjected to dynamic thermal environment and subsequently provide assistance in improving the design against possible deformation due to thermal effects.

Read more

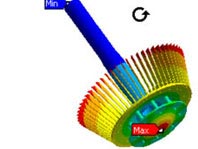

- Vibration Analysis

Our mechanical engineers help product designers to minimize NVH frequencies and provide solutions to dampen the effects of vibration and resulting stress and deformation effects.

Read more - Explicit Dynamics

We assist engineering organizations and product manufacturers to develop product designs that withstand against sudden loads or impacts through our expertise in explicit dynamics simulations that include:

- Crash Analysis

- High and Low Cycle Fatigue Analysis

FEA specialists at HiTech FEA assist manufacturing organizations to estimate fatigue life of their products through high and low cycle fatigue analysis. We provide information on causes and patterns of failure conditions with prediction and growth of the crack and suggest possible ways to improve useful life period.

Read more

- Structural-Thermal

We help in predicting physical effects of structural and thermal loads on product design and provide insights on possible ways to perform optimization for resistance against stresses and deformation.

Read more - Piezoelectric

With structural-electrical coupling, our FEA specialists help in predicting the effects of structural displacements and electrical loads for devices such as fuel injectors, transformers, sensors and transducers.

Read more

We enable manufacturing organizations to visualize their manufacturing processes such as molding, casting, forging, etc. through simulation techniques and determine key improvement areas in equipment designs prior to actual application.

Read more