Fatigue Analysis Services For Engineering Products

Staying ahead in a competitive market requires manufacturers to develop quality products with increased useful life cycle, while keeping costs to minimum.

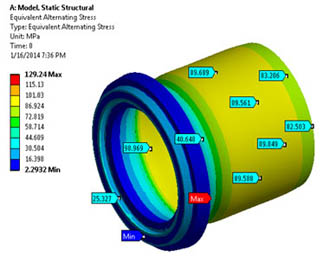

We help manufacturing organizations and design engineers to improve their product life cycle through FE based fatigue analysis. With an in-depth analysis on causes of fatigue failure, formation and growth of crack and prediction of product’s safety margin, we play a crucial role in investigating the product performance and predict possible inspection intervals. Our solutions provide engineers the opportunity to incorporate alternative design strategy such as the use of composite materials, and thereby improve useful life period of the product and also establish warranty schedules effectively.

View ProjectsDomain Expertise/Application Areas:

Reach out to us for fatigue analysis services at info@hitechfea.com or contact us.